Addition Polymerisation

This lesson covers:

- How alkenes can polymerise to form addition polymers

- Drawing and naming addition polymers

- The properties of addition polymers

Alkenes polymerise by opening their double bonds

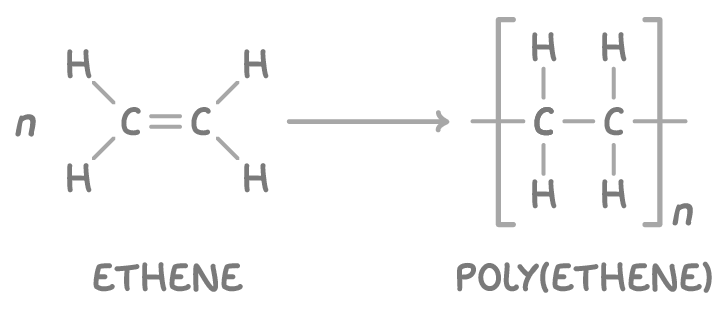

Alkenes contain a carbon-carbon double bond.

This bond can open up, allowing alkene molecules to join end-to-end and form long chains called polymers.

- The individual alkene molecules are called monomers.

- Joining many monomers together is called polymerisation.

- Polymers made this way are called addition polymers because the double bond opens up and monomer units are added to the chain.

For example, ethene monomers polymerise to form the addition polymer poly(ethene):

Drawing polymer repeating units

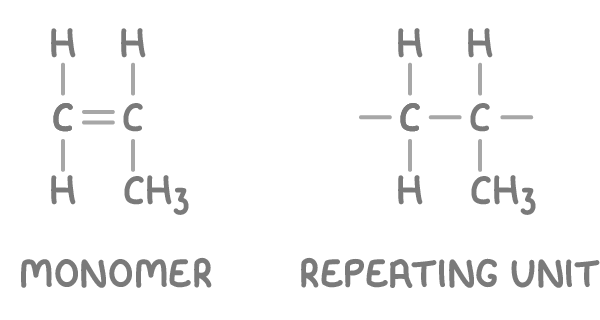

Polymers are made up of smaller repeating units. A repeating unit is the smallest section of a polymer chain that repeats over and over.

To draw the repeating unit from given monomer:

- Replace the carbon-carbon double bond with a single bond.

- Extend single bonds from each carbon atom to represent attachment sites within the polymer chain.

For example, the repeating unit of poly(propene) can be deduced from the propene monomer.

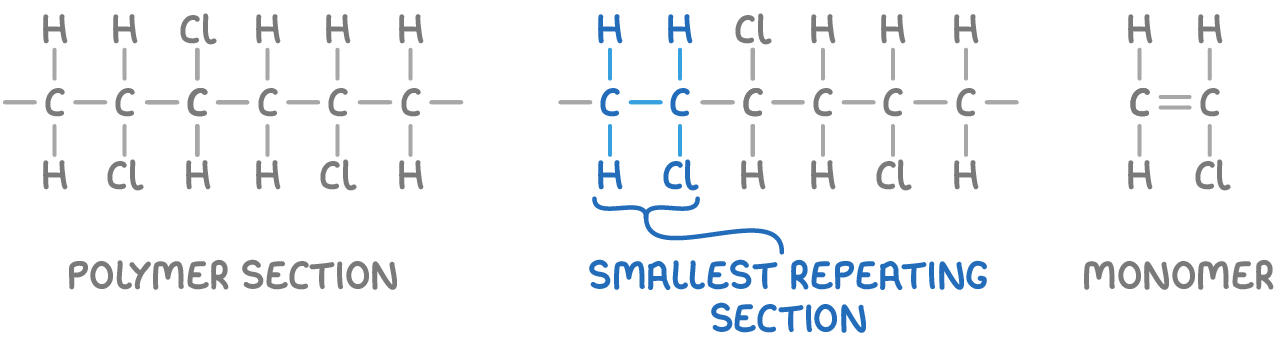

To deduce the monomer from a given polymer section:

- Identify the smallest section that repeats in the full polymer chain.

- Replace the carbon-carbon single bond with a double bond.

For example, the monomer of poly(chloroethene) can be deduced from a section of the polymer chain.

Naming addition polymers

Addition polymers made from alkenes follow systematic naming rules:

- Take the name of the alkene monomer.

- Enclose the monomer name in brackets.

- Add the prefix "poly".

For example, the addition polymer made from butene is poly(butene).

Addition polymers made from alkenes are called polyalkenes.

Physical properties of polyalkenes depend on intermolecular forces

The physical properties of polyalkenes are influenced by the strength of intermolecular forces between the polymer chains:

- Chain length - Longer chains allow more surface contact between neighbouring chains. This strengthens the intermolecular forces.

- Branching - Straight chains can pack together closely in an ordered structure, maximising intermolecular forces. Highly branched chains cannot pack as efficiently, reducing contact between chains.

Longer, straight polyalkenes experience stronger intermolecular forces which requires more thermal energy to overcome. This makes these polymers harder and more rigid. Shorter or branched polyalkenes have weaker intermolecular forces, making them more flexible materials.

The inert nature of addition polymers

Addition polymers are unreactive due to their lack of double bonds and non-polar structure:

- Polyalkenes contain only single covalent bonds. This makes them saturated compounds with maximum stability.

- They also have a carbon backbone lacking any polar groups, giving an overall non-polar molecule.

These factors lead to very low chemical reactivity under normal conditions.

Plastic waste and disposal

Plastic waste is a major environmental issue with over two million tonnes produced yearly in the UK alone.

This is problematic because:

- Most plastics are non-biodegradable due to their unreactive structure.

- Burning halogenated plastic waste potentially produces toxic emissions such as hydrogen chloride.

- Burying waste in landfills is unsustainable.

There are several approaches to dealing with plastic waste:

- Recycle - Remould or crack plastic waste back into useful materials or chemical feedstocks.

- Incinerate - Combust plastic waste and use the heat to generate electricity. Scrub waste gases to reduce environmental impact of combusting halogenated plastics such as PVC.