Culturing Microorganisms

This lesson covers:

- Why microorganisms are cultured in biotechnology

- How bioreactors can be used to produce microbial cultures

- How conditions are optimised inside bioreactors

- Batch fermentation and continuous fermentation

- How to culture microbes in the laboratory

Why are microorganisms cultured in biotechnology?

Biotechnology involves growing cultures of microorganisms, such as bacteria or yeasts, under controlled conditions.

There are two main reasons to culture microorganisms:

- To generate biomass of the microorganisms, for example, for use in producing single-cell protein as animal feedstock.

- To manufacture compounds the microbes synthesise, for example, antibiotics, vitamins, or enzymes.

Achieving maximum yields in the cultivation process is crucial, regardless of the goal.

Primary metabolites and secondary metabolites

The substances produced by microbes in biotechnology can either be described as primary metabolites or secondary metabolites.

- Primary metabolites

- These are substances that are produced in processes that are essential for normal microbial functioning.

- e.g. Ethanol from anaerobic respiration in yeast.

- Secondary metabolites

- These are substances produced in non-essential processes.

- e.g. Antibiotics or plant defence chemicals.

How bioreactors can be used to produce microbial cultures

Bioreactors are used for large, commercial-scale production of microbial cultures. These are essentially large fermentation tanks that are optimised for microbial growth.

Typical components of a bioreactor include:

- A metal or plastic tank with inputs and outputs for liquids and gases.

- Paddles for mixing the culture to ensure an even distribution of food, oxygen, and temperature throughout.

- Probes to monitor pH, temperature, and dissolved oxygen.

- Ports for adding ingredients and removing products.

- A sterilisation system, for example, steam injection.

They also always include some kind of nutrient medium, which is a substance that provides the essential nutrients for microbial growth, in either a liquid form (broth) or a solid form (agar).

How conditions are optimised inside bioreactors

By precisely controlling conditions within the bioreactor, we can accelerate growth rates and maximise product yields.

Key limiting factors that are regulated include:

| Parameter | Control method | Purpose |

|---|---|---|

| Nutrient availability | Fresh medium circulated by paddles | As population size increases, nutrient demand may exceed nutrient supply, so a constant supply ensures microbes have the nutrients they need |

| Temperature | Heating/cooling water jacket surrounds vessel | Too low and bacterial enzymes won't work so bacteria won't grow, too high and bacterial enzymes denature |

| pH | Monitored by a pH probe and automatically adjusted by adding acids/bases | A build up of carbon dioxide may reduce pH, which can inhibit enzyme activity so keeping optimal pH allows microbial enzymes to function efficiently |

| Oxygen levels | Sterile air pumped in | As population size increases, oxygen demand may exceed oxygen supply as aerobically respiring microbes require oxygen |

| Contamination and waste | Steam sterilisation between batches and removal of waste products | Unwanted microbial contamination creates competition from other microbes, and a build up of toxic waste may kill the culture |

Aseptic techniques must be used when culturing microorganisms to prevent contamination with unwanted microorganisms. This ensures that the nutrient medium remains sterile until use and that high yields of the desired product are made.

Batch fermentation and continuous fermentation

There are two main methods for operating fermenters: batch fermentation and continuous fermentation.

- Batch fermentation

- Microbes are grown in a fixed volume in individual batches until nutrients deplete and waste accumulates.

- Each batch is followed by emptying and cleaning of the vessel before starting the next batch.

- Continuous fermentation

- This involves continuously supplying fresh nutrients and removing the culture broth.

- This maintains the growth of the culture indefinitely.

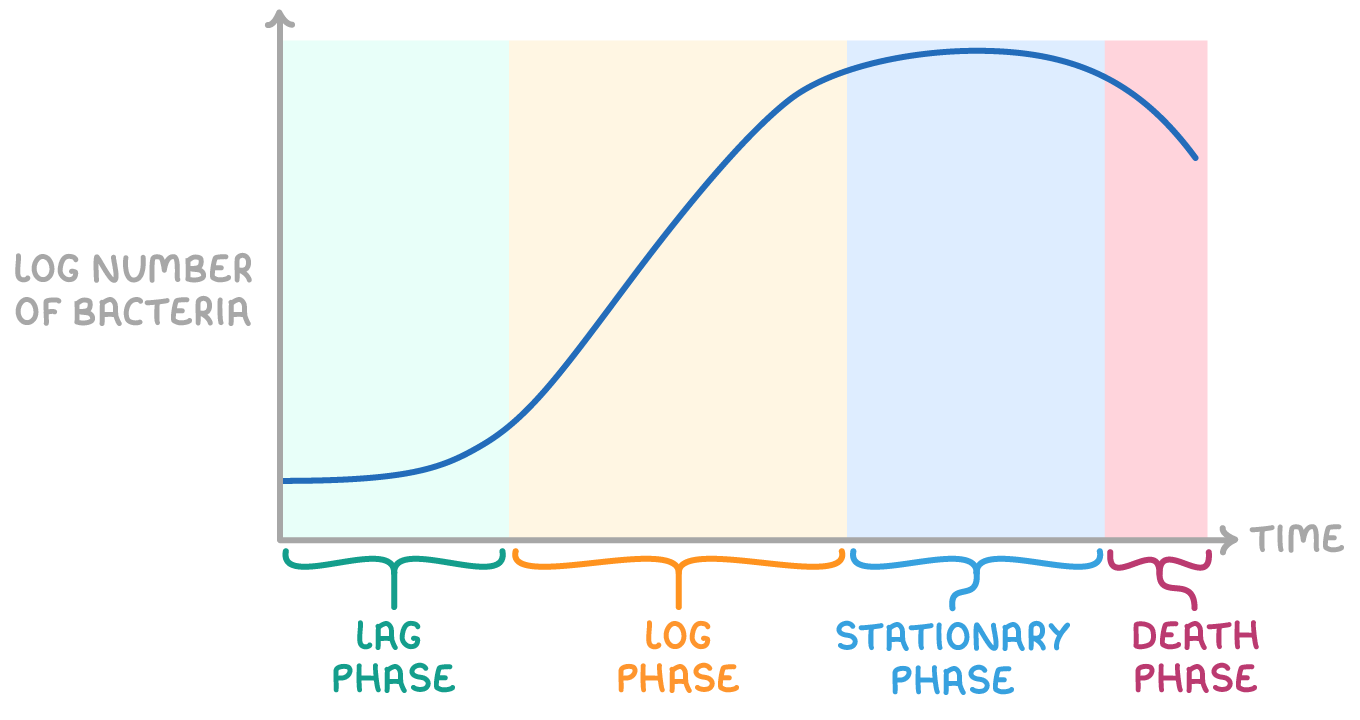

Microbial growth curves in batch cultures

In batch cultures, which is a closed system, microbes follow a standard growth pattern over time.

This growth pattern includes four key phases:

- Lag phase - Cells have slow initial growth as they adapt to their environment and produce essential enzymes.

- Log phase (exponential phase) - Rapid doubling of cell numbers occurs under ideal conditions, and growth rate is at its maximum.

- Stationary phase - Growth rate plateaus as nutrients diminish and waste accumulates, and cell growth is equal to cell death.

- Death phase - Cell death rate exceeds cell growth rate due to resource limitation and build up of toxins.

Batch cultures quickly use up nutrients and accumulate inhibitory by-products. Continuous systems avoid these issues by constantly replenishing nutrients and removing wastes.

How to culture microbes in the laboratory

Microbial cultures can also be grown on agar jelly in Petri dishes under laboratory conditions. This method allows for the study of factors influencing their growth.

How to grow microbes on agar plates:

- Sterilise all equipment before use, e.g. by holding a wire inoculating loop in a Bunsen flame.

- Dip the sterilised wire inoculating loop into a starter culture, like broth that contains a bacterial suspension.

- Transfer the microbes to a Petri dish containing a sterile nutrient medium by lightly zig-zagging the loop across the agar.

- Close the plates and lightly tape them so they are not completely sealed (to prevent growth of anaerobic microbes).

- Label the plates with relevant information, such as the type of microbe, date, and conditions

- Incubate the plates upside down under the required conditions.

- Repeat steps 1 to 6 for a control agar dish with no bacteria.

- Assess microbial growth by observing colony formation on the agar.

Factors that may affect microbial growth

Various factors affecting microbial growth can be investigated.

Some examples and how they can be investigated include:

- Temperature - Incubate duplicate plates at different temperatures.

- pH - Add buffer solutions to the agar to maintain different pH levels.

- Nutrient availability - Prepare agar with varying nutrient concentrations.

- Antimicrobial substances - Add different antimicrobial compounds to the agar plates.

Growth differences can be quantified by counting colonies or using a spectrophotometer to measure culture turbidity, which is an indicator of cell density.