Fermenters

This lesson covers:

- What industrial fermentation is

- Why and how we maintain suitable conditions in the fermenter

- The conditions in the fermenter

Industrial fermentation Microorganisms, such as bacteria and fungi, can be used to create valuable substances, such as penicillin, insulin, mycoprotein or yoghurt. |

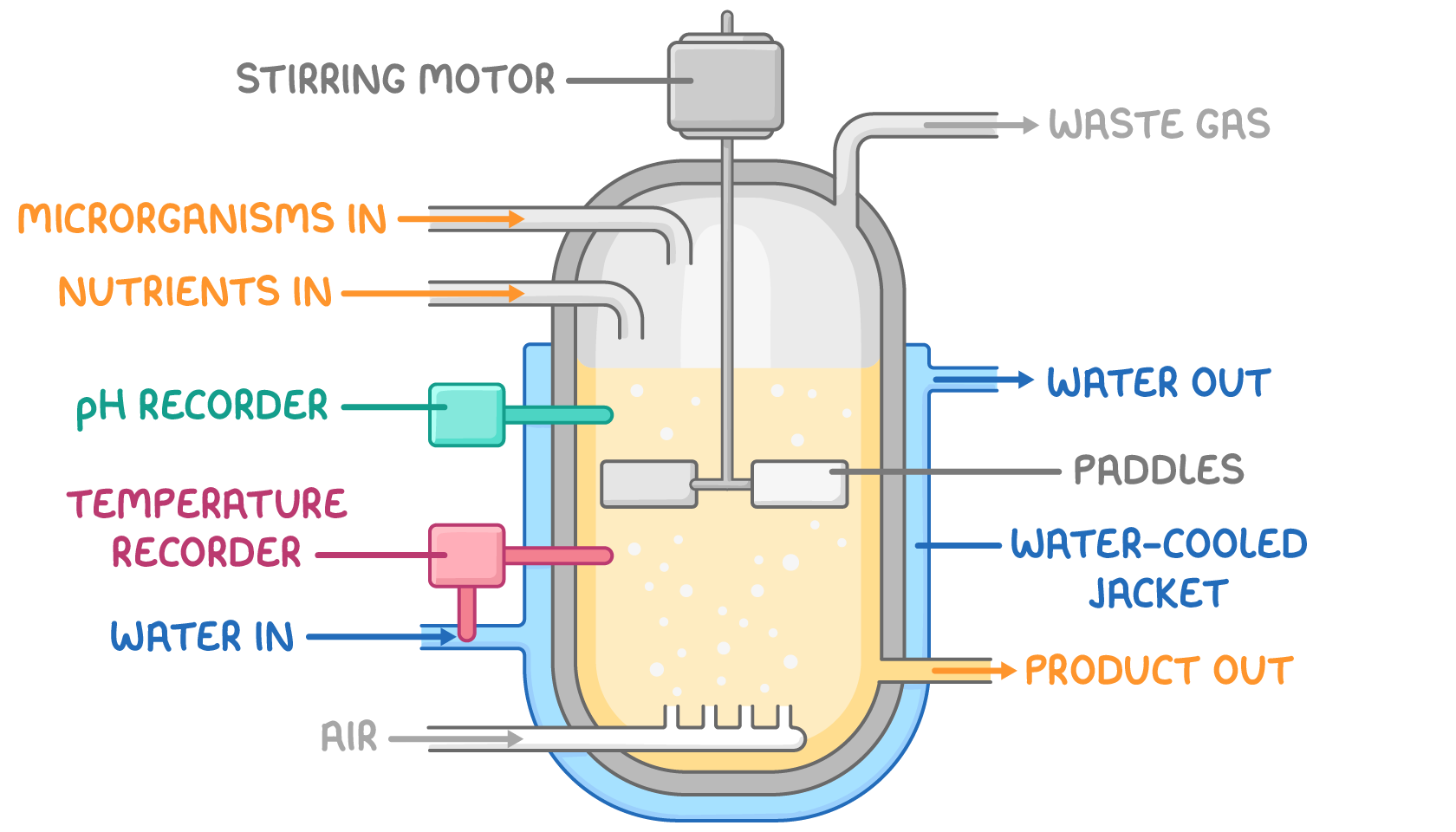

To ensure their optimal growth, these microorganisms are grown in large tanks known as fermenters, where conditions like temperature, pH, and nutrient levels can be monitored and controlled at all times. When done on a large scale, we call this process industrial fermentation. |

Industrial fermenters  |

|

Sterilisation of fermenters Industrial fermenters are designed to facilitate the sterilisation of vessels before introducing the culture medium and microorganisms. Sterilisation is essential to prevent contamination and ensure a controlled environment for the growth of microorganisms. |

What is the primary purpose of industrial fermentation?

Extracting minerals from raw materials

Using microorganisms to transform raw materials into valuable products

Regulating temperature in industrial settings

Enhancing product flavour in food processing

|

In which type of fermentation process is the introduction of oxygen necessary?

Temperature-controlled fermentation

Anaerobic fermentation

Aerobic fermentation

pH-regulated fermentation

|

Why are paddles or agitators used in a fermenter?

To sterilise the vessel

To regulate temperature

To mix and distribute nutrients in the culture medium

To control pH levels

|

In a fermenter, what is the role of a water-cooled jacket?

Mixing the culture medium

Controlling pH levels

Sterilising the vessel

Regulating temperature

|

Why is the addition of nutrients in a fermenter crucial?

To extract final products

To control pH levels

To add oxygen to the liquid medium

To support the growth and metabolism of microorganisms

|